Business Segment Drivers

SideStroem Water Technologies recognizes the need for more efficient industrial processes to reduce the overall ecological impact of industrial production.

One high-impact source of productivity gains is to continuously remove any ethanol that is produced as a byproduct in fermentation broths. Fermentation is a microbial process by which microorganisms convert carbohydrates into desirable metabolic end products. The removal of ethanol serves to avoid ethanol’s inhibitory effect on microbial growth, which already kicks in at ethanol concentrations below 2% (20g/l). This will ultimately enable fermentation processes to run continuously as compared to today’s batch processes.

Commercial drivers for continuous fermentation processes include:

- Lowering the unit production cost (i.e. higher turnover rate) of fermentation through an optimum growth rate of microorganisms and high utilization rate of nutrients.

- Improving production of primary metabolites (e.g. organic acids, amino acids), which are associated with the growth of microorganisms.

- Reducing the size requirement of fermenters since the yield is very high.

- Eliminating washing steps between successive batch processes resulting in reduced water usage and lowering of production costs.

SideStroem’s value proposition

SideStroem’s forward osmosis technology will enable continuous ethanol removal from fermentation broths with minimal loss of target product (most likely, low molecular weight organic compound, peptide, or protein) during the ethanol removal process. This will allow fermentation industries to switch to continuous fermentation processes with all the associated gains.

Market size

According to a market report by Persistence Market Research, the global fermented ingredients market will be worth US$ 40 billion by 2022. It is therefore not surprising that food manufacturers are currently intensifying their efforts to improve fermentation processes.

In a market survey conducted by ForwardOsmosisTech, the forward osmosis market size was estimated at $USD 50.6 ± 28.2 million by ultimo 2021.

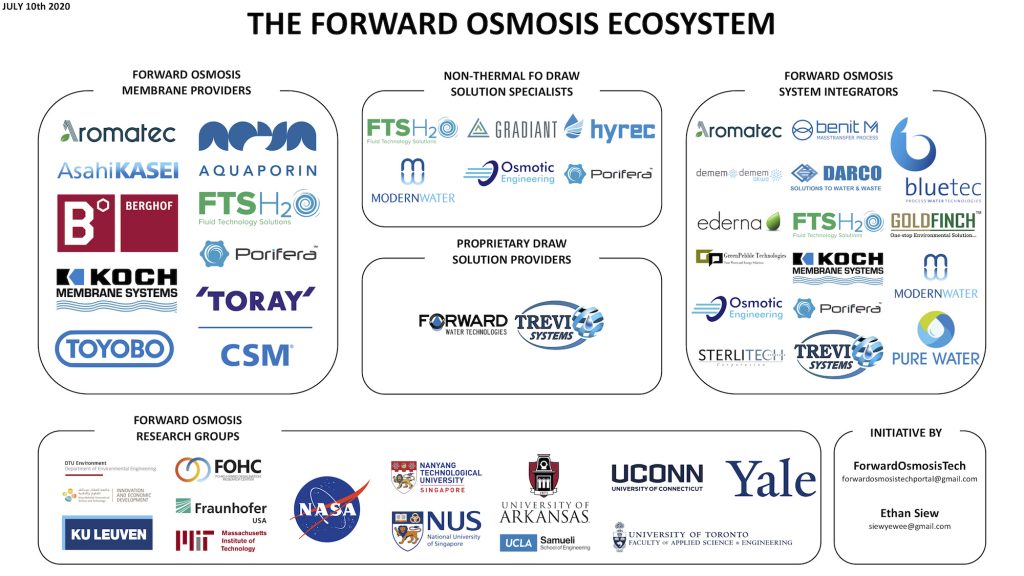

As such, forward osmosis should be considered commercially viable, which is exemplified by the global forward osmosis ecosystem with its numerous commercial players across the entire value chain.