Business Segment Drivers

Zero Liquid Discharge (ZLD) is the ultimate wastewater management & water recovery regime – achieving almost 100% water recovery and eliminating any liquid waste leaving an industrial plant. In industries where water consumption and wastewater discharge are restricted due to dwindling freshwater resources and strains on downstream aquatic environments, water & resource recovery from wastewater streams enables industries to increase their production capacity while – at the same time – reducing their ecological impact. India is at the forefront of imposing and enforcing ZLD regulations and India’s textile & tannery industries are driving the country’s ZLD adoption.

Commercial drivers for ZLD technologies include:

- Ensuring compliance with government discharge regulations to avoid fines and/or shut downs.

- Improving resource recovery from wastewater streams as a means of increasing production capacity.

- Decreasing the overall costs of ZLD given that traditional means of ZLD, such as evaporators, are exceedingly energy-intensive.

SideStroem’s value proposition

Forward osmosis is one of a handful membrane-based low-energy ZLD alternatives capable of significantly reducing ZLD costs. Additionally, SideStroem’s forward osmosis technology will enable simultaneous recovery of both water & valuable solute side streams from wastewater with the following value for industrial end users:

- Decreased OPEX costs of wastewater treatment leading to lower payback time of wastewater treatment systems using SideStroem’s forward osmosis technology.

- Superior resource recovery ensures compliance with discharge regulations while enabling increased production capacity.

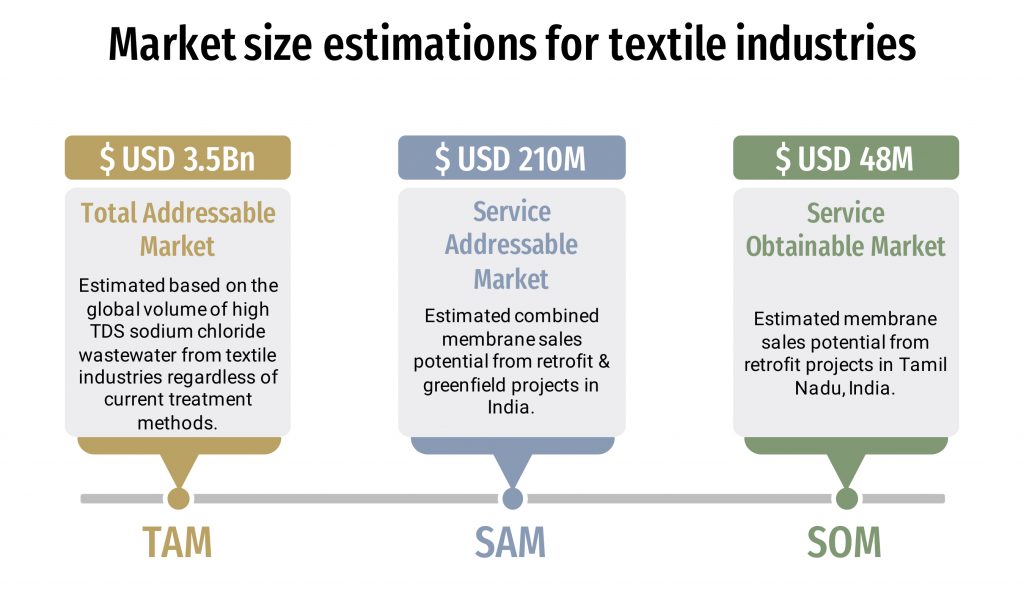

Market size

We estimate a total addressable market size of $ USD 3.5Bn for SideStroem’s forward osmosis technology applied to high TDS (sodium chloride) wastewater from textile industries regardless of current treatment methods. Adding to the total addressable market size comes the market potential for SideStroem’s forward osmosis technology within tannery industries and other industrial wastewater treatment applications.